Exertherm has launched a Bus Duct Monitoring Solution: a cable and sensor based continuous thermal monitoring technology for bus duct electrical power distribution systems.

Exertherm’s Bus Duct Monitoring Solution is a hardwired technology providing 24x7 visual and digital alerts enabling operators to act on the warning signs of dangerous temperature rise before outages occur.

Data centers, and other energy intensive industries, are increasingly opting for the flexibility and ease of deployment of bus duct power distribution systems.

Alan Moug, CEO, Exertherm, says: “The benefits of bus duct power delivery systems are clear. But customers rightly have concerns around potentially dangerous hotspots especially on bus duct joints. Based on decades of experience and listening to our customers, Exertherm’s response was to create an innovative, simple and scalable monitoring solution looking for hotspots to alert users of potential failures before they happen.”

Bus duct power distribution systems allow engineers to route electricity directly to where it is needed. However, constant heating and cooling over time causes expansion and contraction around bus duct joints which can lead to dangerous hot spots. Left unchecked these can cause power outages or fire that can knock out entire facilities.

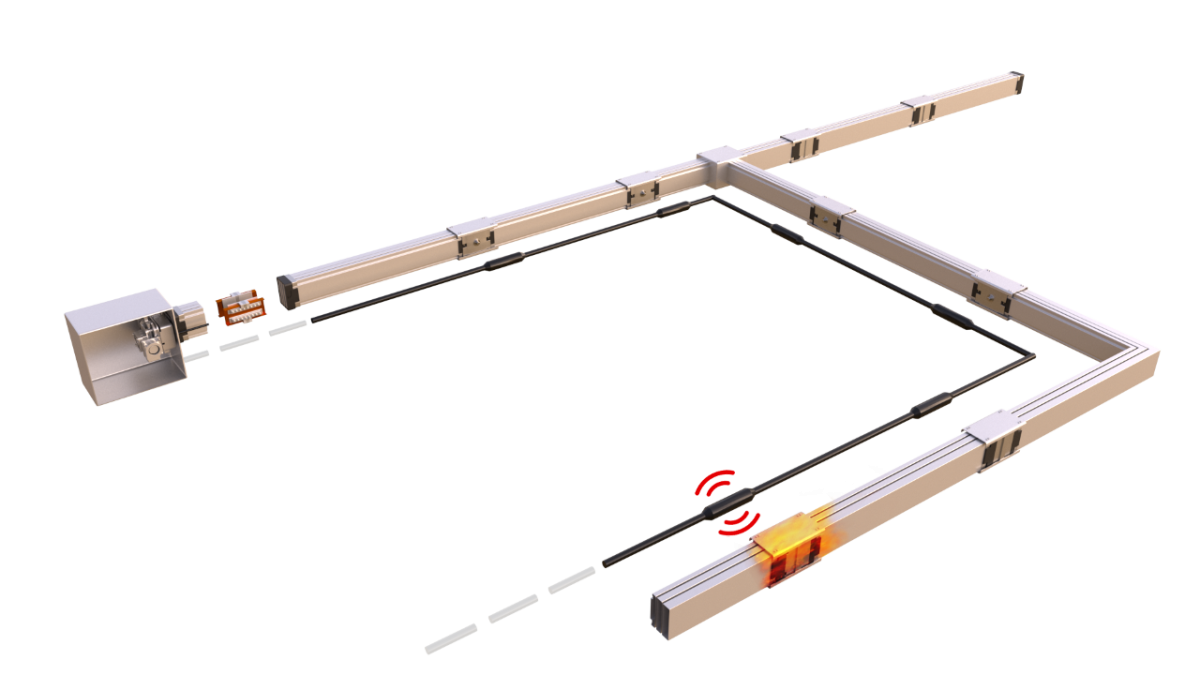

The answer is Exertherm’s Bus Duct Monitoring Solution, which continuously monitors for hotspots at section joints across the entire bus duct installation.

Charles Mann, Sales Director Databar, Anord Mardix, one of the world's leading electrical engineering and manufacturing firms specialising in critical power solutions, says: “Bus duct is the versatile, space-saving and efficient way to route electricity around a facility. When you couple bus duct with a thermal monitoring solution, customers benefit from the most resilient and adaptable power distribution available.”

As a complete plug and play modular system, the Exertherm Bus Duct Monitoring Solution can be installed at the same time as bus duct, avoiding the complexity of retrofit in a live environment. This results in maintenance-free monitoring of all critical joints for the lifetime of the bus duct.

Integrated with EPMS and BMS systems it digitizes electrical infrastructure monitoring for continuous performance.